The Pneumatic Floating Ball Valve is designed for reliable operation in high-pressure and high-temperature applications.

Product Overview

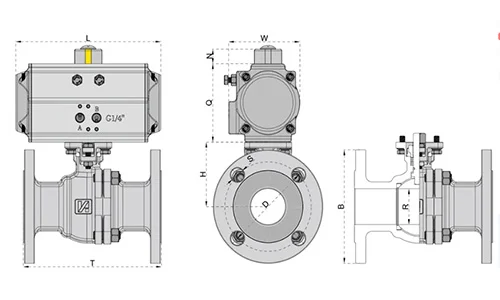

The Pneumatic Floating Ball Valve is designed for reliable operation in high-pressure and high-temperature applications. Featuring a floating ball design with pneumatic actuation, this valve provides excellent shut-off capabilities and quick operation for process control systems.

Technical Specifications

| Size Range | 1/2″ to 12″ (DN15 to DN300) |

| Pressure Rating | Class 150 to Class 600 (PN16 to PN100) |

| Body Materials | Carbon Steel (WCB), Stainless Steel (CF8/CF8M), Duplex Steel |

| Ball Material | Stainless Steel 316, Chrome Plated, PTFE Coated |

| Seat Material | PTFE, RPTFE, PEEK, Metal Seated Options |

| Actuator Type | Double Acting / Spring Return Pneumatic |

| Operating Pressure | 4-7 bar (60-100 psi) Air Supply |

| Temperature Range | -20°C to +200°C (-4°F to 392°F) Standard |

| -50°C to +400°C (-58°F to 752°F) Special Designs | |

| Connection Type | Flanged (ANSI, DIN, JIS, BS), Threaded (NPT, BSP), Socket Weld |

| Leakage Class | ANSI Class IV (Standard), Class VI (Bubble Tight) Available |

Key Features & Advantages

The ball is not fixed to the stem, allowing it to float slightly downstream to create a tight seal against the seat under pressure.

Available in double-acting or spring-return configurations for fail-safe operation in critical applications.

Quarter-turn operation provides quick opening and closing with minimal torque requirements.

Precision-machined components ensure zero leakage when closed, meeting ANSI Class VI standards.

Actuator response times as fast as 1-2 seconds depending on size and configuration.

Available in various material combinations to resist corrosion in harsh environments.

Industrial Applications

Oil & Gas Industry

Chemical Processing

Power Generation

Water Treatment