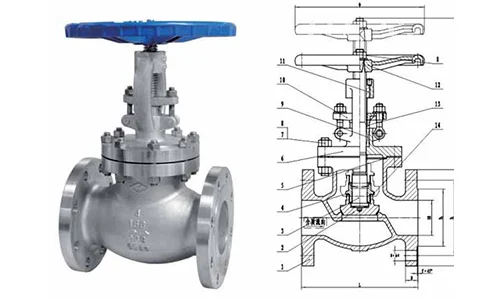

The J41W stainless steel globe valve features flanged connection with pipeline-matched bore size. The disc moves vertically along the seat centerline through stem thread transmission for precise opening height control.

Product Overview

The J41W stainless steel globe valve features flanged connection with pipeline-matched bore size. The disc moves vertically along the seat centerline through stem thread transmission for precise opening height control. Specially designed for pipeline systems requiring accurate flow regulation and tight shut-off in petroleum, chemical, pharmaceutical and other industries.

Core Advantages

Technical Parameters

| Parameter | Standard Specification | Optional Specification |

| Nominal Diameter | DN15~DN200 | DN250~DN400 |

| Pressure Rating | PN16~PN40 | PN63~PN100 |

| Temperature Range | -20℃~200℃ | -196℃~550℃ |

| Connection Type | Flange (RF) | Flange (RTJ), Butt Weld (BW) |

| Operation Type | Handwheel | Gearbox, Electric Actuator, Pneumatic Actuator |

| Leakage Class | ANSI V | ANSI VI (Special Order) |

| Design Standard | GB/T 12235, API 602, ASME B16.34 | |

Material Combinations

| Component | Standard Material | Optional Material |

| Body | CF8 (304) | CF8M (316), CF3 (304L), CF3M (316L) |

| Disc | 304 + Hard Alloy | 316, 17-4PH, Stellite 6 |

| Stem | 304 | 316, 17-4PH, Monel |

| Seat Face | 304/PTFE | Stellite Overlay, Tungsten Carbide Coating |

| Packing | Graphite Braid | PTFE, Flexible Graphite Ring |

Working Principle

When rotating the handwheel clockwise, the stem drives the disc downward along the seat centerline to gradually close the flow path; counterclockwise rotation lifts the disc to open the flow path. The large contact area between disc and seat enables precise flow regulation and tight shut-off.

Structural Features

⚠ Important Installation Notes

Typical Applications

Selection Guide

| Operating Conditions | Recommended Configuration |

| Regular Water/Steam (PN16~PN40) | CF8 Body + 304 Disc (Standard Type) |

| Corrosive Media (Acid/Alkali) | CF8M Body + 316 Disc + PTFE Seal |

| High Temperature (≥200℃) | CF8 + Stellite Overlay Seat + Graphite Packing |

| Cryogenic Service (≤-50℃) | CF3/CF3M Body + Cryo-Treated Components |

Maintenance

Routine Maintenance

Scheduled Maintenance

Customization Services

This product can provide the following customized solutions: