The HC41X Silencing Check Valve is a spring-assisted, silent check valve designed to prevent water hammer and reduce noise in pipeline systems.

Product Overview

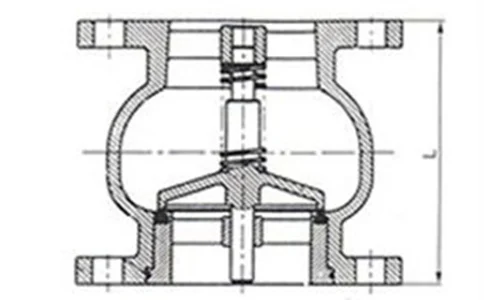

The HC41X Silencing Check Valve is a spring-assisted, silent check valve designed to prevent water hammer and reduce noise in pipeline systems. Its unique disc design and spring mechanism ensure smooth, quiet operation while maintaining reliable backflow prevention.

Key Features

Technical Specifications

| Parameter | Specification |

| Size Range | DN50~DN600 (2″~24″) |

| Pressure Rating | PN10~PN16 (Class 150) |

| Temperature Range | 0℃~80℃ (standard), -20℃~120℃ (extended) |

| Cracking Pressure | 0.01~0.05MPa |

| Closing Time | 1~3 seconds (adjustable) |

| Connection Types | Flanged, Wafer, Lug |

| Body Material | Ductile Iron (GGG50), Cast Steel (WCB),Stainless Steel (304/316) |

| Disc Material | Stainless Steel with EPDM/NBR sealing |

| Spring Material | Stainless Steel 304/316 |

| Test Standards | ISO 5208, EN 12266, API 598 |

Working Principle

The HC41X valve utilizes a spring-loaded disc that opens with forward flow and closes immediately when flow stops or reverses. The spring force ensures positive closure independent of gravity or mounting position. The specially designed disc and flow path minimize turbulence, resulting in quiet operation and preventing water hammer effects.

Structural Features

Applications

Installation & Maintenance

Installation Requirements

Maintenance