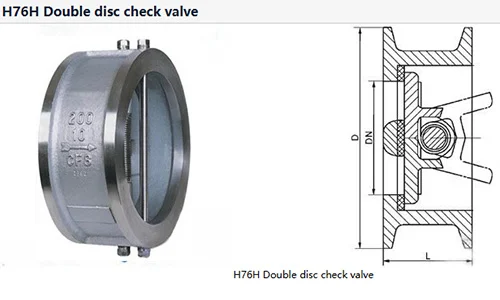

The H76H Dual Plate Wafer Check Valve is specifically designed for water systems, featuring a dual-disc swing structure with quick closing, water hammer protection, and low pressure drop characteristics.

Product Overview

The H76H Dual Plate Wafer Check Valve is specifically designed for water systems, featuring a dual-disc swing structure with quick closing, water hammer protection, and low pressure drop characteristics. Particularly suitable for water system pipelines in water supply/drainage, fire protection, and HVAC applications to effectively prevent medium backflow.

Core Advantages

Technical Parameters

| Parameter | Specification | Remarks |

| Nominal Diameter | DN50~DN1000 | 2″~40″ |

| Pressure Rating | PN10~PN25 | Class 150~300 |

| Temperature Range | 0℃~80℃ | Short-term up to 100℃ |

| Body Material | Ductile Iron QT450-10/Carbon Steel WCB | Epoxy-coated interior |

| Stainless Steel | ||

| Disc Material | Stainless Steel 304 + NBR/EPDM | |

| Connection Type | Flange Connection (RF/FF) | GB/T 17241.6 standard |

| Closing Time | 0.3-0.8 second | |

| Opening Pressure | ≤0.01MPa | |

| Testing Standard | GB/T 13927 API 598 | |

Working Principle

The H76H Dual Plate Wafer Check Valve adopts a dual-disc swing structure. When water flows forward, water pressure pushes two semi-circular discs to rotate open around the shaft; when water stops or reverses, the discs close quickly under the combined action of self-weight + spring force + water pressure to prevent backflow. The specially designed damping device effectively reduces water hammer impact during closing.

Structural Features

Typical Applications

Installation & Maintenance

Professional Installation Guide

Scientific Maintenance Plan

Selection Guide