Product Overview

The H46H Dual Plate Check Valve features a dual-disc structure with quick closing, water hammer protection, and low pressure drop characteristics. Specifically designed to prevent medium backflow, it is widely used in petroleum, chemical, power, water supply and drainage applications.

Core Advantages

Technical Parameters

| Parameter | Specification | Remarks |

| Nominal Diameter | DN50~DN1200 | 2″~48″ |

| Pressure Rating | PN10~PN40 | Class 150~300 |

| Temperature Range | -20℃~+150℃ | High-temperature version up to 200℃ |

| Body Material | Cast Iron HT200/Ductile Iron QT450/Carbon Steel WCB/Stainless Steel CF8 | |

| Disc Material | Stainless Steel 304/316 + NBR/FKM | Selected based on medium |

| Connection Type | Flange Connection (RF/FF) | Complies with GB/T 17241.6 standard |

| Closing Time | 0.5-1 second | |

| Testing Standard | GB/T 13927 API 598 | |

Working Principle

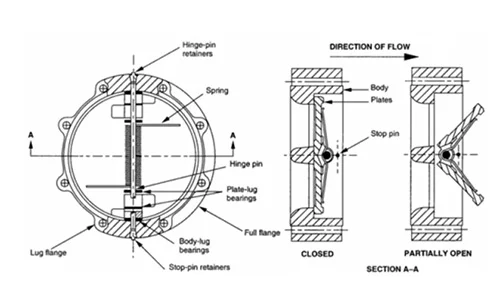

The H46H Dual Plate Check Valve adopts a dual-disc swing structure. When medium flows forward, fluid pressure pushes two semi-circular discs to rotate open around the shaft; when medium stops or reverses, the discs close quickly under their own weight and reverse medium pressure to prevent backflow. The spring-assisted design ensures reliable closing in any installation position.

Structural Features

Typical Applications

Installation & Maintenance

Professional Installation Guide

Scientific Maintenance Plan

Selection Guide

Important Notes