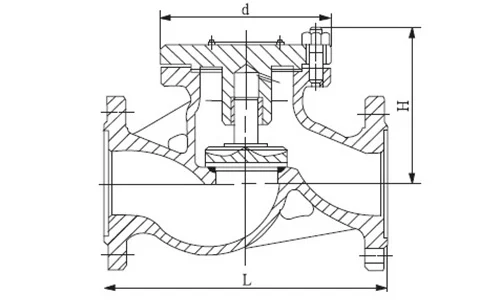

The H41H Lift Check Valve features a vertical lift design with flanged connections. The disc moves vertically along the valve body axis, automatically opening/closing based on medium pressure to effectively prevent backflow.

Product Overview

The H41H Lift Check Valve features a vertical lift design with flanged connections. The disc moves vertically along the valve body axis, automatically opening/closing based on medium pressure to effectively prevent backflow. Specially designed for high-pressure and high-temperature applications in petroleum, chemical, and power industries.

Key Features

Technical Specifications

| Parameter | Standard Specification | Optional Specification |

| Nominal Diameter | DN15~DN300 | DN350~DN600 |

| Pressure Rating | PN16~PN40 | PN63~PN160 |

| Temperature Range | -29℃~425℃ | -196℃~550℃ |

| Body Material | Carbon Steel (WCB) | Stainless Steel (CF8/CF8M), Alloy Steel (WC6/WC9) |

| Disc Material | Stainless Steel + Hard Alloy Welding | Solid Alloy Steel, Monel Alloy |

| Sealing Type | Metal Hard Seal | Soft Seal (Graphite/PTFE) |

| Connection Type | Flanged (RF) | Flanged (RTJ), Buttweld (BW) |

| Applicable Media | Water, Steam, Oil | Corrosive Media, High-Temperature Gas |

| Design Standards | GB/T 12236, API 594, ASME B16.34 | |

Operating Principle

The valve opens when medium pressure lifts the disc vertically. When flow stops or reverses, the disc closes rapidly under its own weight and reverse pressure, creating a reliable seal. The spring-assisted closure ensures positive shut-off regardless of installation orientation.

Structural Features

⚠ Critical Installation Notes

Typical Applications

Selection Guide

| Service Condition | Recommended Configuration |

| Standard Water/Steam (PN16~PN40) | WCB Body + Stainless Steel Disc (Standard) |

| High-Temp/Pressure Steam (≥425℃) | WC6/WC9 Alloy Steel Body + Alloy Steel Disc |

| Corrosive Media | CF8/CF8M Stainless Steel Body + Special Alloy Disc |

| Low-Temperature Service (≤-29℃) | LCB Body + Cryogenically Treated Components |

Installation & Maintenance

Installation Requirements

Maintenance Schedule